How many nuts and bolts are there in the Sydney Harbour Bridge? Well, oddly enough, only a handful. Rivets were used instead, some 6,000,000 of them.

The majority of the steel for the bridge’s girders came from Britain, but the government contract stated that all rivets were to be made from Australian steel. At one point, doubts arose as to whether this requirement was being adhered to. On October 24 1929 the following article appeared in the Sydney Morning Herald;

AUSTRALIAN STEEL USED

Mr R.H. Maxwell, in a letter to the Editor, states that the Victorian Premier (Sir William McPherson) expressed himself rather forcibly in refutation of an allegation that nuts and bolts for the Sydney Harbour Bridge were being imported.

Mr Maxwell added: “To travellers in ferry boats, which passed Dorman, Long’s workshops, it is common knowledge that stacks of small hessian bags are to be seen near the wharf, which apparently have been unloaded from overseas freighters. As these small bags do not contain steel girders, there is a lingering suspicion in the minds of some persons that the said bags contain imported nuts and bolts for the bridge.“

The letter was shown to the Minister of Works (Mr Buttonshaw) yesterday, who stated that it was part of the contract that all rivets in the bridge should be made from Australian steel.

So far, he said, all the steel used had been rolled at Lithgow, inspected there by an inspector of the Public Works Department, and dispatched to Melbourne to be made into rivets.

Most of them, added the Minister, were returned to Sydney by boat. The completed bridge structure would be riveted together. A few bolts and nuts might be used temporarily by Dorman, Long, to hold the large parts together prior to riveting. The contract did not say that that should not be done.

Dr. Bradfield had also assured him that careful supervision was kept over this work, and that all the rivets were made from steel rolled at Lithgow.

Even today, Lithgow residents should feel a little surge of pride when crossing the old ‘coathanger’. Their steel is holding it up!

MISS BRIDGE! – BLUE MOUNTAINS BORN

Another reason for Lithgow and the Blue Mountains to be proud in relation to the bridge is the work of a young woman called Kathleen Butler. Born at Mount Victoria (her father was the stationmaster), Kathleen worked in the office at the Lithgow steel mill when she left school. She took a great interest in engineering and in the manufacture of steel.

She later joined the public service and was appointed confidential secretary to Dr Bradfield, the designer of the bridge. Due to her knowledge of steel she was given responsibility for the world-wide tendering process. Miss Butler travelled to London, where she set up an administration office. The Lithgow Mercury of April 30 1924 reported on her departure;

Visiting Lithgow on Saturday to bid farewell to her sister was Miss Kathleen Butler, formerly of Mount Victoria, and now of Hurlstone Park. Miss Butler is confidential secretary to Mr. J.C. Bradfield, chief engineer to the North Shore bridge and city railway, and sails by the Ormonde today to take charge of the office in London, established to confer with Messrs. Dorman. Long and Co., the successful bridge tenderers.

Dubbed ‘Miss Bridge’ , Kathleen published many articles and progress reports during the years of construction.

The reason Mr McPherson had defended himself so forcibly regarding the ‘Lithgow’ rivets was because he was not only the Victorian Premier, but sole proprietor of the machinery company which had won the contract to manufacture them; McPherson’s Pty Ltd in Melbourne.

Naturally the Harbour Bridge contract provided the company with a wonderful advertising opportunity;

AHOY SAILORS….BEWARE!

As the bridge neared completion, the Harbour Trust issued a warning to shipping, Referring to the sections of the great arch, an editorial reprinted in the Hobart Mercury (April 30 1929) stated;

Some day, if we don’t have too many strikes, they will meet in the centre, and some jubilant riveter will drop a hammer, which will land on the pet corn of an old gentleman travelling up the river on a Parramatta steamer. It is about the dropping of hammers and bolts and other bits of things that the warning has been issued. Nothing has escaped from the bridge so far, except a bit of orange peel; but if a bolt did fall from such a great height it could do great damage to any vessel it struck, apart from the possibility of killing somebody on deck.

In August the following year the rivets did cause a problem, though not by falling on a ferry boat. One windy night a thick rope attached to a panel was blown against hot rivets in a forge and caught alight. The watchman telephoned the foreman, who drove to the bridge from his home in great haste. Braving the high wind he climbed up the girders and extinguished the fire. (Examiner, August 16 1930)

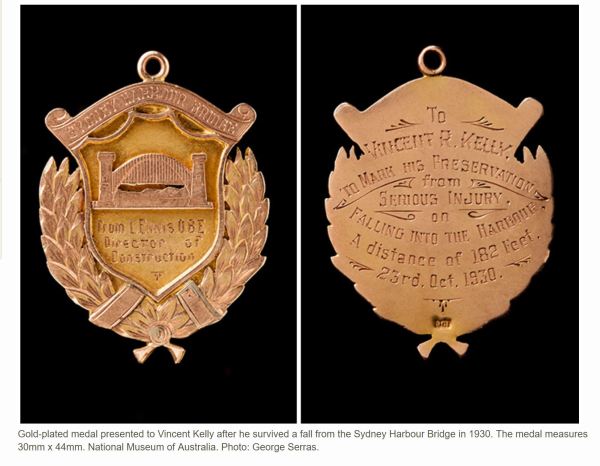

There was another drama in October 1930 when worker Vince Kelly lost his balance while riveting and fell into the harbour. Miraculously he survived with only broken ribs. He was presented with a gold fob watch and a medal.

By 1932, 100,000 defective rivets had been cut out and replaced, at a cost of 2/- per unit. Mind you, the government was at pains to point out that this was a very low percentage compared to bridges of similar size and construction.

HARBOUR BRIDGE POPPING ITS BUTTONS…..

In July 2013, former Federal MP Ross Cameron controversially suggested on the ABC programme The Drum, that the beloved Bridge was past its use by date;

The 6 million rivets (like buttons on a shirt) were heated in coking-fueled furnaces on the Luna Park site before modern welding techniques (which are more like “stitching”). The rudimentary furnaces allowed differing levels of penetration by steel-damaging nitrogen and ash. Each rivet now has variable load bearing and surface qualities. Some of the “buttons” have started to pop. In March this ear, a fastening failure caused a two-square-metre steel panel to shear off the arch – it could easily have fallen onto the carriageway below.

Dear me, that sounds pretty alarming. I wonder whether we could sue Victoria?

If you would like to watch a video of the bridge construction featuring riveting CLICK HERE

IN THE 1950S, TWO WHITE CATS LIVED ON THE BRIDGE.

Another Riveting story from Pauline, Many thanks

Tee hee, very witty Larraine.

Good and interesting story! Thanks

I’m delighted you enjoyed reading it Sebastian.